It’s all Part of the Job – Transformer Anchorage Design

Keeping heavy equipment bolted down

VANCOUVER, Washington August 24, 2015. Welcome to the second installment of “It’s all part of the job,” WRK’s series that documents and explains various aspects of working as a structural engineer. This week we sat down with Scott Howard, Associate Principal, and Alexandra Kuschell, Design Engineer, to learn more about transformer anchorage.

WRK provides structural engineering services for new and existing substation structures to our public and private power utility clients. One of the services offered by WRK Engineers is equipment bracing/anchorage for equipment inside buildings and high-voltage power substations, ensuring equipment is secure, stabilized and remains operational during and after a major seismic event.

One specific type of work we perform is retrofit anchorage for high-voltage power transformers. From wikipedia: “A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. Commonly, transformers are used to increase or decrease the voltages of alternating current in electric power applications.” Transformers are also one of the most important and expensive components in the modern power grid which requires them to remain fully operational and energized when we perform work on them.

At WRK we focus on high-voltage power equipment with voltages of 69 kV and above. High-voltage transformers tend to be much larger and more secluded than the distribution transformers that are commonly seen around populated areas. For example, a 500 kV Transformer can weigh more 600,000 lbs and stand 4 stories tall. Failure of high-voltage equipment in substations can become a serious threat to system performance if it isn’t properly secured to a solid foundation.

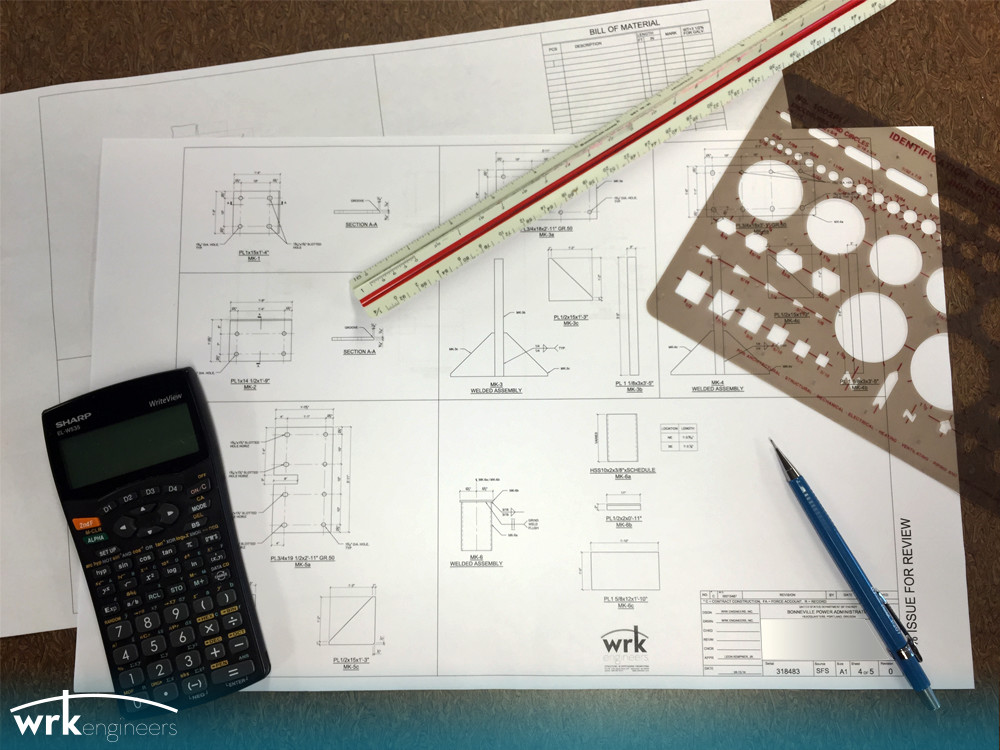

Tools of the Trade – Calculations and notes are often completed on plans before being sent to a drafter for revisions.

An engineer working on anchorage is responsible for designing a post installed seismic anchorage system for the transformer. The process begins with multiple site visits to take detailed measurements. From there the engineer performs calculation of lateral loads acting on the transformer, design of steel baseplates and connections to the transformer and the design of steel baseplates and connections to the concrete footings on which the transformer sits. Special factors like anchorage location, constructability, and practicality must be considered when designing anchorage to avoid potential problems. Since these pieces are custom designs they require the engineer to generate more highly detailed steel shop drawings as compared to standard design drawings.

Once the anchorage has been designed the calculations and drawings are submitted to the client who has them produced by a steel fabrication shop and installed on the transformers.